The problems of the annual formation of industrial waste are common to a wide group of industries, particularly chemical, petrochemical, coal, gas, and wood processing. The most typical wastes of these industries are coal tar, waste oils, oil sludge, filter cakes, coal slime, sawdust, wood shavings, etc.

Most of these materials and components pose a significant environmental threat. Waste occupies large areas and penetrates soil and water; gradual thermochemical transformation of waste is accompanied by the release of hazardous substances. The most common methods of industrial waste disposal are the following: burial, removal of impurities, storage, and reuse for its intended purpose, use as secondary raw material in oil refining and coal preparation, pelletizing, pyrolysis, gasification, and combustion. Most of the treatment and cleaning methods are quite ineffective for large volumes of industrial waste.

At the same time, many enterprises are forced to incur heavy losses due to environmental fines associated with ineffective waste disposal or its absence. Disruptive technologies are required for efficient waste disposal. However, their creation and adaptation require significant economic costs at the initial stage.

Municipal waste is no less dangerous for humanity. In terms of component composition, accumulated volumes, and rates of annual formation, they are practically not inferior to industrial ones. In countries with undeveloped economies, municipal solid waste is considered even more hazardous than industrial waste. The most typical municipal solid waste includes cardboard, paper, plastic, polyethylene, rubber, food debris, etc. Landfilling, thermal treatment, and incineration with energy generation are popular disposal methods for such waste. Holubˇcík et al. used slow pyrolysis of shredded used car tires and plastic packaging.

The research has confirmed that pyrolysis allows for the production of valuable products with minimal damage to the environment. Bala-Litwiniak and Radomiak have shown that waste glycerol can be successfully used as a fuel in combination with wood pellets. Glycerin with a fraction of no more than 4.5% improved the quality of the pellets and the environmental performance. Dudy ´nski et al. carried out a test gasification of leather waste on a laboratory and industrial scale. As a result, a producer gas was obtained with a heating value of 4.1–6.5 MJ/m3. Dudy ´nski et al. concluded that gasification of waste leather may be more promising than incineration, mainly due to greater environmental safety. However, the rate of the annual increase in municipal waste is so high that the factories for their utilization manage to process no more than 20–30%. The main difficulty lies in the need to sort waste to ensure high economic performance.

Unfortunately, in many regions, management mechanisms and regulatory documents have not been formed for the effective separation of waste. As a result, numerous landfills increase in volume every year. Waste disposal technologies without preliminary sorting are important.

The article discusses the modern achievements in the field of thermal recovery of industrial and municipal waste. The average accumulation rate and calorific value of typical wastes were analyzed. The focus is on the opportunities to exploit the energy potential of high-moisture waste, low-grade liquid components, and fuel slurries. With consider the relevant results in the field of combustion, pyrolysis, and gasification of such fuels.

The main attention is paid to synergistic effects, the influence of additives, and external conditions on the process performance. Vortex combustion chambers, boilers with burners, and nozzles for fuel injection, grate, and fluidized bed boilers can be used for the combustion of waste-derived liquid, high-moisture, and slurry fuels.

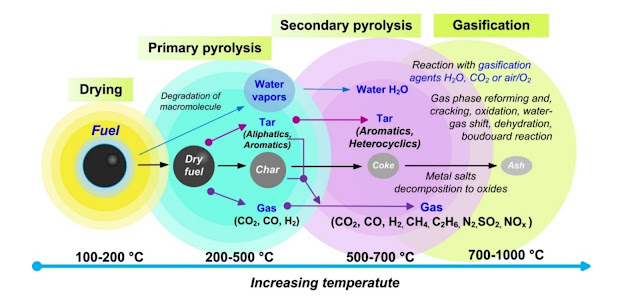

The following difficulties are possible: long ignition delay, incomplete combustion, low combustion temperature and specific calorific value, high emissions (including particulate matter, polycyclic aromatic hydrocarbons), fast slagging, and difficult spraying. A successful solution to these problems is possible due to the use of auxiliary fuel; boiler modifications; oxy-fuel combustion; and the preparation of multi-component fuels, including the use of additives. An analysis of methods of waste recovery in the composition of slurries for fuel gas production showed that there are several main areas of research: pyrolysis and gasification of coal–water slurry with additives of oil waste; study of the influence of external conditions on the characteristics of final products; and the use of specialized additives and catalysts to improve the efficiency of the pyrolysis and gasification. The prospects form improving the characteristics of thermochemical conversion of such fuels are highlighted.

Conclusions

(i) Almost all typical industrial and solid domestic waste has a calorific value comparable to low-grade fuels. The average calorific value of such waste is 7–12 MJ/kg. As a consequence, this waste can be considered promising for energy production. This approach helps to reduce the rate of depletion of fossil fuels, expand the fuel base of many countries, and reduce their economic and energy dependence.

(ii) The combustion of waste-derived liquid, high-moisture, and slurry fuels can be efficiently implemented using boilers of various modifications such as vortex combustion chambers, boilers with burners, and nozzles for fuel injection, grate, and fluidized bed boilers.

(iii) The combustion of waste-derived fuel slurries and high-moisture fuels can be complicated by a long ignition delay time, low combustion temperature, and low specific calorific value. However, this approach provides wide possibilities for varying the composition of the mixture, atomization, increasing the completeness of fuel burnout, and reducing some hazardous emissions.

(iv) The combustion of fuel mixtures, in contrast to the combustion of individual components, provides more opportunities for stabilizing important process parameters (combustion temperature, calorific value, etc.) and obtaining synergistic benefits (for example, a significant reduction in sulfur oxide emissions).

(v) The present review of pyrolysis and gasification of waste-derived fuel slurries summarizes the main parameters influencing the optimization of the yield of gaseous products. Temperature is one of the most important factors affecting the yield and properties of the end products of pyrolysis and gasification. Optimal process temperatures in terms of maximizing gas yield are above 600 ◦C. High temperatures and long residence times favor the formation of non-condensable gaseous products due to secondary decomposition reactions.

(vi) Pyrolysis and gasification in a steam medium are more efficient in terms of maximizing the yield of hydrogen compared to air. From this point of view, the use of water-containing slurry fuels is a promising direction. A substantial part of the gasifier steam requirement can be covered by the generation of steam from the slurry.

(vii) The processes of pyrolysis and gasification of oil wastes in the slurry fuels is an effective option for maximizing gas and liquid products and a promising way to dispose of accumulated waste as fuel with low energy losses. This could conserve fossil fuels and solve the problem of increasing energy demand.